Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

When at work, nearly every employee is compelled to do good and make a positive contribution to their team and organization. But sometimes their knowledge, or lack thereof, can hinder their ability to do just that.

When there’s a lack of knowledge or an information deficit, it can lead to wasted time:

But, there are human factors that can also get in the way of resolving an information gap.

While it would make logical sense for an employee to ask more questions when they require additional information, that doesn’t always happen. The human ego can, at times, lead these same great employees to avoid asking more questions because they think they should know the answer or they fear being perceived as incompetent.

Unfortunately, when employees don’t seek out those answers, they are likely to just make something up or come to their own, potentially wrong, conclusion. Occasionally, this approach can turn out just fine, reinforcing the undesirable behavior. But, when this approach fails, it can cause costly errors that are detrimental to the entire enterprise.

Wouldn’t it be nice if you could ensure your team has the information they need when they need it? A visual workplace can help you achieve that goal.

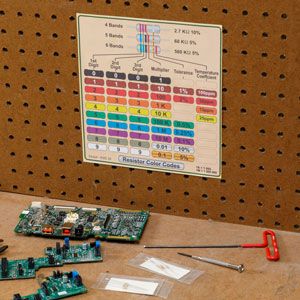

In a visual workplace, critical information is conveyed through visual devices, positioned at the point of need, that can be understood at-a-glance. Because visuals are easy to understand, an effective visual workplace can improve safety by reinforcing training and eliminate wasted downtime that had previously been spent searching, asking or waiting for information.

For instance, when storeroom shelves are well-labeled, employees don’t have to waste time searching for something or accidentally grabbing the wrong thing. Helping them find what they need at-a-glance instantly improves efficiency.

The concept of the visual workplace was introduced in the 1990s by Gwendolyn Galsworth, Ph.D., who is considered the world’s leading expert on the concept. In the 2017 edition of her book "Visual Workplace: Visual Thinking," Dr. Galsworth likens a workplace that lacks visuals to trying to reach a destination without signs, signals or lines on the road.

“You can probably make it, but you are likely to pay a terrible price,”

she states.

Every day during your commute you are surrounded by visual devices that give you information when you need it. From speed limit signs to lane closures, you encounter visual devices that nudge you in the right direction and help you successfully make it to your destination. This concept works because humans are visual beings. In fact, 50% of human brain function is devoted to finding and interpreting visual information.

“The visual workplace is about answering all the questions that anyone has related to work: questions about what is known as well as unknown; questions spoken out loud as well as those on a sub-vocal level; questions that are commonplace as well as those so specialized that only a few people think to ask them,”

says Dr. Galsworth.

When put to use in the workplace, the goal is to provide essential information in a visual, non-verbal format that is easily understood at a glance and is located at the point of need for anyone and everyone who needs it, all without asking a single question. When information is conveyed in this manner, it ensures that everyone can understand what is being communicated, even in a multi-language workforce. For organizations struggling to find experienced workers due the growing skills gap, visual devices can be invaluable by helping less experienced employees learn the job quickly and effectively.

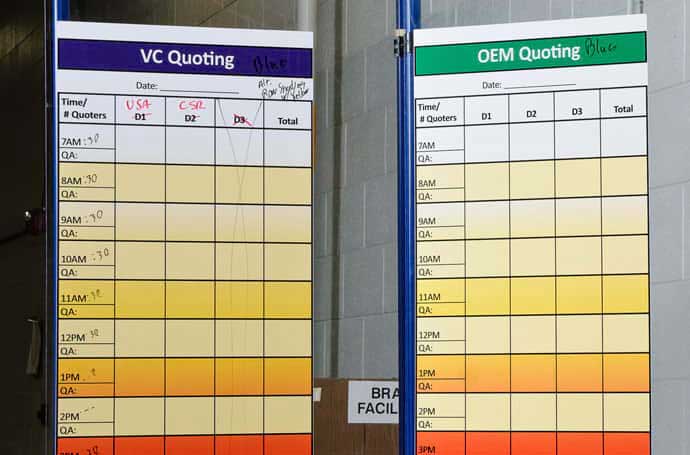

A continuously improving work environment means constant change. Many lean concepts, including Lean 5S, Total Productive Maintenance (TPM), Kaizen (Continuous Improvement) and other lean activities can benefit when visual devices are incorporated, often helping to sustain the improvements and ongoing initiative.

Visuals ensure lean improvements remain clearly visible, readily understood, and consistently adhered to long after the Kaizen improvement event is over, preventing employees from reverting to old habits. However, while closely related to lean manufacturing, Dr. Galsworth makes it clear that visual workplace is not lean or lean’s little helper. The two should be considered “equal and powerful partners in operational excellence.”

Dr. Galsworth goes on to clarify, “Lean addresses the time-driven facets of your operations. Visuality addresses the informational landscape.”

Visual workplace is a powerful tool all on its own and Dr. Galsworth notes that it can often be easier to implement, and much more effective, when put into place prior to lean implementation. When completed first, Dr. Galsworth says “...visuality grooms the work environment as well as the work culture and paves the way for a resounding lean success.”

Organizations that have implemented an effective visual workplace system experience a number of benefits.

Visual devices help employees quickly recognize and respond with the correct action. For example, when an employee sees a sign identifying a pinch point on a machine, they know to pay attention and take steps necessary to stay safe.

Visual devices — such as labeling on inventory, processes and general facility identification — help reinforce employee training and guide workers to complete their tasks by helping them find what they need quickly. In addition, safe state, equipment identification and safety signs all help keep processes running smoothly, reducing downtime.

A primary cause of waste is information deficits — employees simply lacking the knowledge they need to do their jobs efficiently and effectively. To find the information they need, employees often waste valuable time and motion searching, waiting, retrieving, reworking…or just plain giving up! Visual devices, such as one point lessons, can keep employees up-to-date on new or revised standards or work methods for a specific machine or task by providing a visual standard operating procedure right at the point of need.

One of the primary reasons organizations around the world implement a visual workplace is because of the benefits it offers for knowledge acquisition among employees. Because employees tend to learn by seeing, workplace visuals can play an important role in job training. That’s because visual devices, such as one point lessons, can help reduce the need for training by visually reinforcing processes and steps. Visuals make it easier for employees to do their jobs and get their tasks done on time, with fewer mistakes and less stress.

Dr. Galsworth has written a few books that can help you get started on your path to a visual workplace:

Her book "Visual Workplace: Visual Thinking" provides a deeper explanation of the concept and offers a roadmap for how to go about creating an effective visual workplace. Brady has the tools you need to make your visual workplace a reality, including:

Minimum Level Indicators

Required Personal Protective Equipment Notice

Safety and Fire Protection Equipment Visuals

One Point Lessons

Inventory Labels

Point-of-Need Safe Work Instructions

Safety Padlock Labels

Lockout Tagout Procedure Labels

Traffic Intersections

Emergency Egress Markings

Department Information Signs

One Point Labels

Source: Galsworth, Gwendolyn. (2017). Visual Workplace: Visual Thinking. New York, NY: CRC Press.

Learn more on how to stabilize equipment performance and reliability.

Learn More

Learn more about one of the most widely adopted techniques from the lean manufacturing toolbox.

Learn More

Learn how to use lean visuals more effectively by implementing visual workplace techniques in your facility.

Download Now