Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Digitize data capture and automate your workflows with ease and accuracy.

Be lockout-ready with helpful kits and stations stocked with durable, priced-right devices and padlocks.

Shop Padlocks Shop Kits & Stations

Learn more about the pros and cons of preprinted labels and custom on-demand printing.

Learn to control hazardous energy with our eight-step LOTO procedure guide.

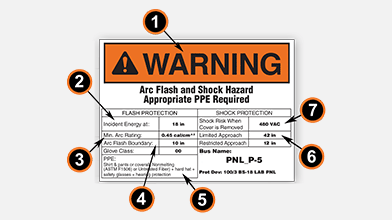

Learn how to comply with OSHA’s arc flash labeling requirements via the 2024 NFPA 70E standard.

Ensure you choose the right labels for your lab environment applications with our guide.

When one size, color or text doesn't fit, customize it!

Plus, reorder custom products with a click of a button!

Start New Order How To Reorder

Experience automated efficiency with Brady’s

full line-up of printer applicators and label feeders

Select a material based on key attributes for your specific application

Search Materials