Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

In a world that heavily depends on electrical power, the safety of electrical equipment is critical. It's not only about maintaining power supply but also about safeguarding the well-being of those who operate these systems.

According to the Electrical Safety Foundation International (ESFI), the majority of electrical fatalities occur in electrician and construction occupations, followed by installation, maintenance and repair occupations. The private industry is responsible for the majority of these fatalities.

One essential aspect of electrical safety is the proper labeling of industrial electrical and control panels. Proper labeling not only helps prevent accidents but also ensures compliance with different safety standards. This guide will give you practical steps to meet electrical panel labeling standards to create a safer and more efficient work environment.

Electrical panels and electrical control panels provide electricity to buildings, equipment and machinery through an organized circuit system. But as the scope and complexity of electrical systems increases, so does the risk of safety incidents due to improper or lack of labeling. Effective industrial electrical panel identification helps workers identify critical circuit information, understand safety risks and quickly find components and locations for servicing and safe operations.

The primary purpose of industrial electrical control panel labeling is safety. Safety labels on breaker panels are imperative for warning workers, preventing accidents and responding to emergencies. In the midst of a malfunction, a well-labeled electrical panel becomes a lifesaver. For example, compliant arc flash labeling warns workers of dangers and instructs them on key considerations when servicing, such as approach restrictions and proper PPE.

Precise identification of breakers and circuit information is essential for the efficient service and function of industrial electrical panels systems. When an electrician conducts maintenance work, accurate labeling guides them to the correct breaker, and keeps maintenance efficient and downtime minimal. It also minimizes the risk errors that pose a threat to those in the immediate vicinity and the areas power is supplied to.

Electrical panel labeling is regulated by several entities, with no one universally applicable set of standards for electrical labeling. The key players in this arena are:

Each offers standards and best practices to follow.

OSHA is a government agency that enforces workplace safety regulations, including for electrical work, and ensures employers are compliant with safety standards. As part of the United States Department of Labor, OSHA’s purpose is to “ensure safe and healthful working conditions for workers by setting and enforcing standards and by providing training, outreach, education and assistance.”

OSHA's regulations for electrical installations and equipment aim to ensure that employees are protected against hazards, ranging from small electric shocks to explosions, associated with their work that could be physically harmful. Many of these regulations are derived from ANSI standards.

Some applicable sections of OSHA 29 CFR 1910 related to electrical panel safety and identification labeling include:

ANSI, the American National Standards Institute, is a nonprofit organization that handles the U.S. voluntary standardization and conformity assessment system. Although ANSI doesn't have the power to enforce rules, it sets guidelines that many companies willingly follow.

In relation to electrical panel labeling, certain sections of ANSI Z535 provide guidelines on how to label for clarity and safety. Some of these include:

The NFPA, a global nonprofit organization established in 1896, is all about preventing “death, injury, property, and economic loss due to fire, electrical, and related hazards.” One key contribution is the National Electric Code (NEC), which sets safety standards for electrical wiring and equipment installation in the United States.

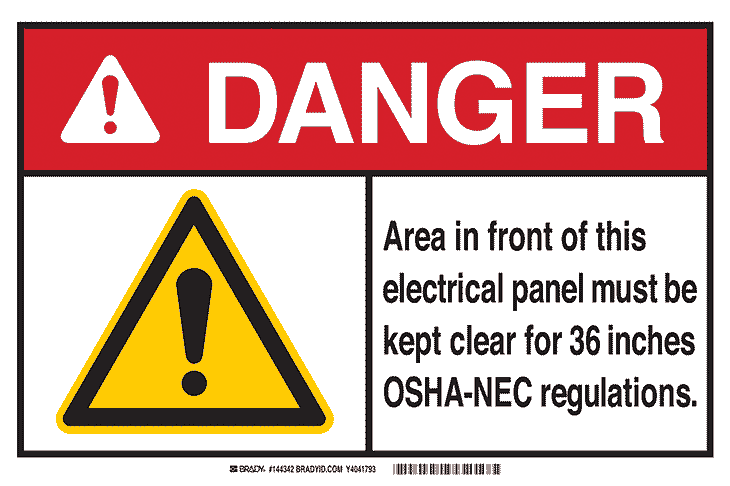

The NEC, although not a law, is often referred to in state-level regulations and offers guidance for labeling electrical panels. Relevant sections of NEC for industrial electrical panel labeling include:

The information needed on an electrical panel label can vary depending on the workplace and equipment used. However, there are a few key elements that are usually required for safety and compliance. These include:

These general guidelines can be adjusted based on local regulations and equipment specifications. Make sure to check relevant codes and standards for specific requirements.

You should consider several factors when labeling electrical equipment.

Labeling your electrical equipment is not only a best practice but also a requirement under various regulations. To determine what specific regulations apply in your state and industry, refer to resources such as the National Institute of Standards and Technology's guide to United States Electrical and Electronic Equipment Compliance Requirements, or OSHA regulations.

Roughly half of the states in the U.S. run their own OSHA programs, while federal OSHA enforces its regulations in the rest of the states. You can find out which states have their own plans. If you're in a “state-plan state,” you can find the state OSHA's website for more information. Most state OSHA programs have their regulations available online.

If you're in a federal OSHA state, you can hop over to osha.gov and check out their Regulations page. They've got plenty of online resources to help you out. Consider your company's industry — they've got specific regulations that might apply to you. Once you've identified the relevant standards, you can follow these best practices for labeling your electrical equipment.

Selecting the right materials for your labels is crucial to ensure that the materials stay legible and intact over time. It's important to consider durability and visibility requirements. Consider factors like heat resistance, especially for equipment that operates at high temperatures, and longevity, particularly for outdoor equipment exposed to different weather conditions. Here are a few label ideas to get you started.

When designing your labels, ensure the labels identify the circuit or equipment they correspond to, including voltage and current ratings, as well as any safety warnings. You can use specialized label printers to create customized labels that meet your specific needs. And don't forget to use contrasting colors and large, clear fonts to make the labels more visible and easy to read.

The placement of labels on equipment is equally important. Labels should be placed where they can be easily seen and read by workers. Avoid placing labels on areas that might be subject to wear and tear or obscured by other objects. For electrical panels, labels should ideally be placed next to the corresponding circuit breaker.

Use panel identification labels that indicate which panel the label corresponds to. This helps prevent confusion and ensures workers can quickly locate the correct circuit for maintenance or emergencies.

While proper labeling is a critical component of electrical equipment safety, it's important to remember that labeling alone is not sufficient. There are other aspects of electrical safety that companies must also consider:

Labeling electrical panels is crucial for workplace safety, but it's just one part of the puzzle. By following these best practices and taking other safety measures into account, you can make your workplace safer for your employees and satisfy the necessary regulations.