Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Workers across a variety of industries deal with hazardous materials each day. Fortunately, through careful labeling and management, the vast majority of these employees never sustain any harm from the presence of the chemicals.

According to the Occupational Safety and Health Administration (OSHA), employees have a right to know (RTK) about dangerous chemicals and gasses so they can wear proper protection and handle them carefully, and a major part of how workers and users are informed is through labeling.

There are a variety of labeling standards and regulations to address this imperative concern, including OSHA’s HCS, GHS, the NFPA Diamond and the topic of this article - the Hazardous Materials Information System, otherwise known as HMIS.

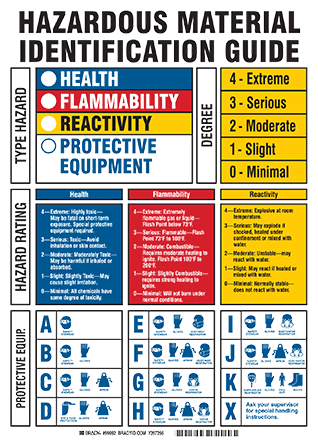

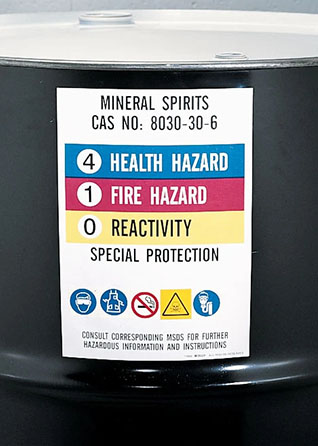

The HMIS uses colors, numbers and symbols to communicate information to employees about specific chemicals. Just by reading the label, an employee can learn how harmful a particular substance is and the recommended personal protection equipment (PPE) when handling it. This labeling ensures any employee who is trained on the system can make safe decisions in the workplace.

The American Coatings Association administers the HMIS and issues regular updates and guidelines to increase the safety of people handling dangerous chemicals. This program is designed to support people in the workplace, rather than support HAZMAT responders.

The HMIS system uses colors to identify the different ways a chemical could be hazardous — through flammability (red), reactivity/instability (yellow) or causing health problems (blue).

With this process, an employee can learn how to protect themselves and why they should, just by glancing at a label.

The first thing you will notice is that there are four different sections on the label that are divided into different colors. This differentiation is meant to help you scan the information to learn the risks of each chemical or gas you handle. Here is a breakdown of the four colors.

By scanning the label, you can glean how flammable and reactive a substance is and then immediately apply the correct PPE before handling it.

Within each color label, there is a box with a number placed inside. This number falls on a scale of 0-4, with 4 being the most serious. Each color has its own specific definition of what the numbers mean. For example, a four in the red section highlights how the substance is considered flammable, while a four in the blue section warns that the substance is highly toxic to humans.

As an example, here is a breakdown of a chemical’s flammability levels so you can see how numbers 0-4 provide information to the employees handling it.

There’s a significant difference in danger between a substance that needs to be heated to extreme levels before it can ignite and a substance that could spontaneously ignite just by coming into contact with the air. Knowing these numbers can alert employees to critical chemicals.

The final part of the HMIS label is the PPE code. These codes are often carried over for HCS labeling because they have been accepted as an industry standard. Here’s what you need to know about PPE labeling.

There can be a lot more to remember when it comes to PPE. Your business could benefit from hanging up posters that explain these letter codes to anyone who handles potentially hazardous substances within your organization.

HMIS is not a regulatory obligation. Instead, it’s a standard that many companies and industries have adopted to streamline communication. This system is essential for industries related to manufacturing, chemical production and product development. Painters also use it, as it was developed by the American Coatings Association. That said, the HMIS rating scheme was designed to be compatible with workplace labeling requirements for OSHA’s HazCom Standard.

The HMIS is different from the OSHA's Hazard Communication Standard (HCS), although related. The HCS is a requirement for chemical manufacturers who assign these labels for their customers to use while the HMIS is a system that can be used for compliance.

HMIS can align with HCS standards. A company may use the information provided by a chemical manufacturer to assign an HMIS label to a substance. It’s OK to have multiple forms of safety communication and chemical labeling within your organization as long as there is standardization and unification across the company.

HMIS is similar to the hazardous materials labeling system created by the National Fire Protection Association (NFPA). Both labels use the same four colors — blue, red, yellow and white — and alert employees to the flammability, health concerns and instability of various substances.

However, there are some differences that include:

HMIS is very close to the Hazardous Materials Identification Guide (HMIG), and oftentimes the two are used interchangeably. HMIG labels often have more information about PPE to ensure employees are wearing the right safety equipment, but this information is often found on HMIS labels as well.

If you don’t currently implement HMIS labeling, you can take steps to adopt this industry standard within your organization. It is important to reiterate that HMIS is a suggested industry standard while OSHA rules are requirements.

As you start assigning HMIS labels to various substances, make sure they stay compliant with OSHA and accurately reflect the toxicity and flammability of each chemical. OSHA has several publications on hazardous materials to help with this process. Your employees will be able to learn about various chemicals and safely handle them. Here are a few steps to streamline the implementation process.

Your implementation process will require a mixture of signs and labels across your company. Each individual chemical will need to be evaluated and labeled based on HMIS standards. When a new substance arrives at your business, it will need to go through the labeling process.

You will also need hazardous material signs that tell your employees what these labels mean. Signs need to be placed in break rooms, in areas where the chemicals are handled and throughout the workplace. With the right signage, someone who has never heard of the HMIS will still be able to read and understand your new labels.

OSHA states that employees need to receive safety data sheets that relate to harmful chemicals. These data sheets should come with any chemicals that require HCS labeling.

Make sure your employees can easily access the sheets to review them before handling chemicals. Keep them in an accessible place within your organization. You can also reference them during the HMIS labeling process to make sure each substance is marked correctly based on HCS information.

Finally, implement training within your organization to update current employees on the HMIS and HCS. You will want to retrain your workers periodically to remind them what these labels mean.

Also, update your safety onboarding process to discuss HMIS labels so new team members understand how to read them.

The transition to the HMIS might take some time, but it’s worth the effort. Your employees can handle any substance safely with the right PPE. They will know why a particular chemical is dangerous and take steps to be careful with the materials.