Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

How to properly label your electrical equipment to comply with 2024 NFPA 70E

The Occupational Safety and Health Administration (OSHA) is an organization that provides workplace guidance about electrical safety-related work practices in the form of regulations, like 29 CFR 1910.333(a), which emphasizes the use of safety-related work practices to prevent electric shock and other injuries when working on or near energized equipment.

While OSHA has specified the above regulation, you may not know exactly how to put it into action. This is why the National Fire Protection Association (NFPA) is needed. Through their NFPA 70E Standard for Electrical Safety in the Workplace, you can comply with OSHA regulation 29 CFR 1910.333(a). Their most current edition (2024) outlines 6 primary responsibilities facilities must meet:

Alerting personnel to electrical hazards is critical to safety. One of the best ways you can do this is visually through labels. Arc flash labels are a requirement listed in NFPA 70E Article 130.5.

The owner of electrical equipment is responsible for the documentation, installation and maintenance of the marked label. So, if you rely on contractors to perform electrical work, it’s your responsibility to ensure these elements are implemented or updated. Make sure you’re using high-performance labels that can outlast their environment.

According to NFPA 70E, labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized. These labels communicate the electrical hazards an employee may be exposed to, including the potential for an arc flash incident.

Label where un-terminated wires or cables needing superior abrasion and chemical resistance exist.

Label where terminated or unterminated cables and wires that may be curved or become curved exist.

Label where terminated cables or wires that may need additional abrasion or chemical resistance exist.

Label where large amounts of data needs to be communicated in a small area, such as fiber optic cables.

Label where large amounts of voltage exist, either on the ground or mounted up high in a facility.

Label where multi-conductor cables or bundled wires/cables exist.

Old Label Versions. The recent update allows labels applied prior to the effective date of this edition of the standard to be acceptable if they complied with the requirements for equipment labeling in the standard in effect at the time the labels were applied (unless changes in electrical distribution system render the label inaccurate).

Document and Review. Document the method of calculating and the data to support the information for the label and review for accuracy at intervals not to exceed 5 years. Where the review of the data identifies a change that renders the label inaccurate, the label shall be updated.

The owner of the electrical equipment shall be responsible for the documentation, installation and maintenance of the marked label.

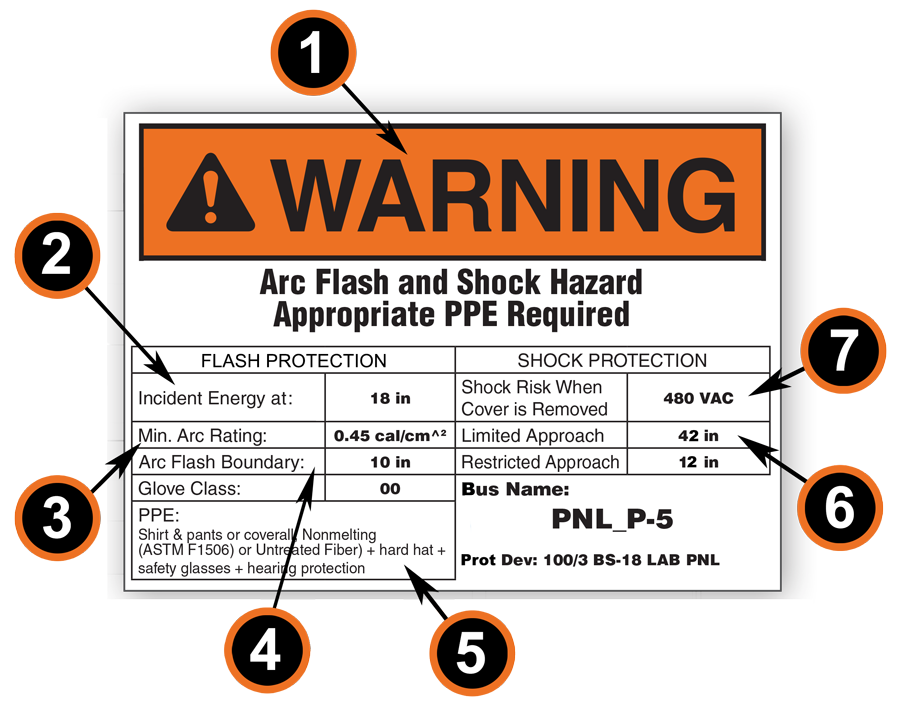

Shop Brady’s Arc Flash LabelsNow that you’re familiar with the equipment that needs labeling, here are the elements you will need to include in your arc flash labels.

A common guideline is to use the "Danger" header when the voltage is over 600 or when the incident energy is over 40 cal/cm2. If it is less than this threshold, an orange "Warning" header is typically used.

The Institute of Electrical and Electronics Engineers (IEEE) defines this as "the dimension between the possible arc point and the head and body of the worker positioned in place to perform the assigned task."

A measurement in calories/cm2 or Joules/cm2 of thermal energy at a working distance from an arc fault.

This is the shortest distance at which a person working at the time of an arc-flash may receive permanent injury (the onset of a second degree burn or worse) if not properly protected by flame-resistant (FR) clothing.

Each hazard risk category requires a different level of protection. Categories range from 1 to 4. Category "0" was removed in the NFPA 70E 2015 Changes.

These boundaries are defined in more detail in our Arc Flash Workplace Safety Guide. The "prohibited approach" boundary was removed in the 2015 NFPA 70E edition.

The voltage of the equipment.

Retraining should occur every 3 years, and employees must also be retrained if their job duties change, or when procedures are not being followed (as observed by annual inspections or supervision).

Training should include:

Training sessions must be documented and verified at least annually, and participants must be able to demonstrate knowledge. To help keep your workplace safe and compliant, Brady Safety offers a custom approach to Arc Flash Training.

Identify your arc flash safety needs — quickly.

USE THE ARC FLASH SAFETY CHECKLIST TOOL

The NFPA 70E Standard for Electrical Safety in the Workplace is revised every three years by you (the public) and industry. In the 2024 edition, you’ll find proactive ways to stay safe when working with energized equipment and systems. It features:

The 2024 edition also includes additions and reorganized sections. Some highlights include:

The NFPA 70E standard was updated for 2021, including adding detail to term definitions, clarifying requirements and reorganizing information for a more logical progression. The most notable changes are:

Let our safety professionals guide you with assessments, audits, training and more.