Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Brady has a responsibility to be a good steward of the environment, no matter where we are in the world.

Our environmental priorities are focused where we know we can make the greatest impact, help the environment and where it makes good business sense. Our environmental efforts are focused both internally, by making our operations more environmentally-friendly, and externally, through our product development process and through helping our customers with their own environmental and safety needs.

Go into greater detail on Brady’s sustainability efforts by reading our 2023 ESG Report.

View the full ESG reportBrady’s most direct impact on the environment relates to the natural resources and energy we consume. In this report we have provided data around our Scope 1 (direct) and Scope 2 (indirect) emissions from our operating facilities, either owned or leased, around the globe. We are striving to identify ways to reduce our carbon intensity across Brady's global footprint.

| Year: | 2021 | 2022 | 2023 |

|---|---|---|---|

| Carbon intensity (GHG emissions / net sales): | 3.2% | 2.9% | 2.7% |

To support our effort to reduce greenhouse gas emissions, Brady generates and uses renewable energy at the following manufacturing facilities:

Geothermal Energy — Egelsbach, Germany

Solar Energy

For more information about our renewable energy, please check out our FY2022 ESG Report, where we featured spotlights of our sites that are using solar energy.

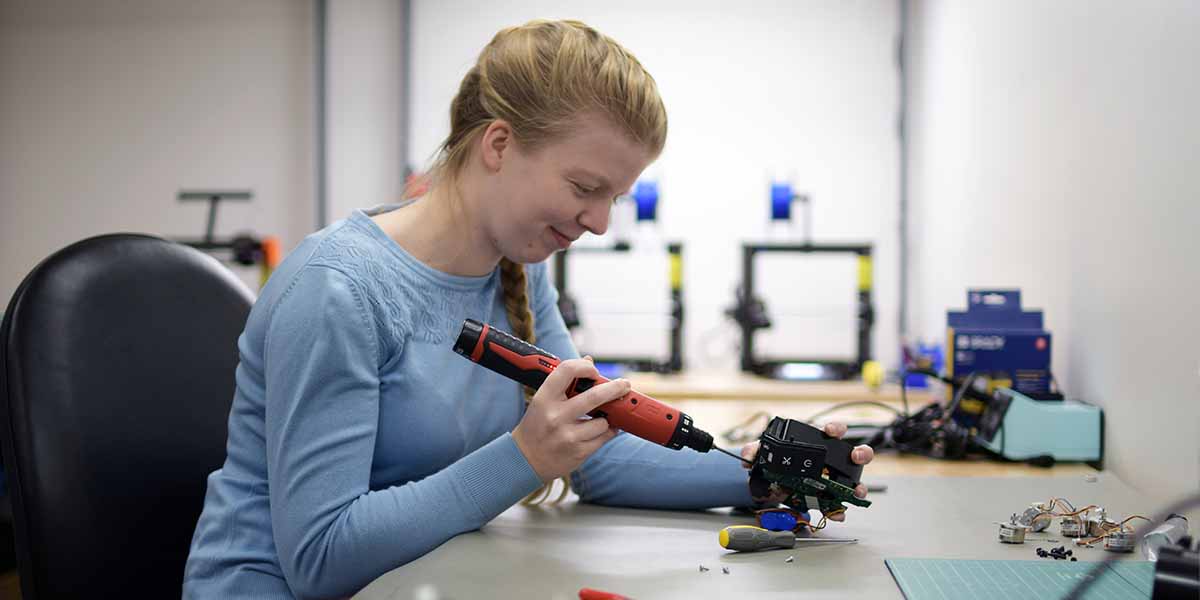

Brady prides itself on making products that last. To help extend the life of our printers, Brady’s regional service centers offer technical services, including upgrades and repairs, on all of our benchtop and portable printers in our portfolio. In FY23, Brady’s North America Technical Services Team completed 4,273 service requests, including upgrades and repairs, helping to increase the lifetime of our printers. Printers that reach their usable lifetime are sent to an electronic waste recycling contractor.

Our servicing team helps extend the lifetime of our printers, contributing to the circularity of our products.

Across Brady, we are focusing on ways to reduce our waste to landfill. Here we highlight sites that made great strides in FY23.

The Brady Signals site in LaRochelle, France launched an initiative to reduce waste to landfill, reducing waste to landfill by 95%. Partnering with a local waste management provider, the site has been able to recycle all of their raw material waste. The site also partnered with a company that is able to reuse their PVC waste for extrusion of tubes and profiles. In FY23, the site recycled over 1.9 metric tons of material.

In Egelsbach, Germany, there is nearly no waste to landfill. Most of the waste is sent to thermal incineration to generate energy, while paper, metal, wood, and electronics are sent to recycling facilities. This site in particular has been focused on reducing waste to landfill created by their shipments. For larger shipments, the site reuses packaging and filling materials from suppliers, when they are able to. For smaller shipments they have implemented Wave Wrap machines that utilize recyclable corrugated cardboard sheets to create packages that fit the item being shipped. This system reduces the need for package filler and uses up to 80% less packaging material than conventional packaging, reducing the waste being sent to customers.

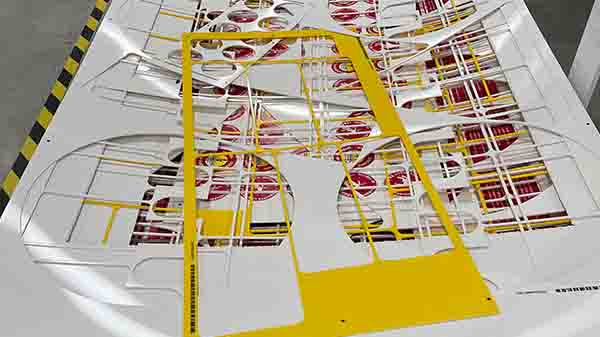

Every quarter, Brady’s Tijuana, Mexico site hosts a Bright Ideas Challenge, encouraging all employees to develop solutions to improve plant operations. Winners receive a prize and their idea is implemented into the plant’s operations. In the first quarter of FY23, an employee submitted an idea that allows a rotary die to be repaired on-site, which extends the life of each die and reduces the number of dies sent for disposal as a result of the manufacturing process. After implementation of this idea, 97 dies were repaired.

Brady focuses its R&D efforts on a variety of track and trace applications, pressure sensitive materials, identification and printing systems, software, and the development of other workplace safety-related products.

The majority of Brady’s R&D spend supports our identification products. Material development involves the application of surface chemistry concepts for top coatings and adhesives applied to a variety of base materials. The design of our identification and printing systems integrates materials, embedded software, a variety of printing technologies and product scanning and identification technologies to form a complete solution for customer applications. In addition, the R&D team supports production and marketing efforts by providing application and technical expertise.

For every new development product, Brady evaluates opportunities to implement sustainable aspects without compromising the integrity of the product. All aspects of the product are evaluated, including manufacturing, design, packaging, sourcing, raw materials, and waste, both industrial and consumer. As the product progresses through the development process, these evaluations are reviewed for additional opportunities.

We pride ourselves on making a safer, more productive world, and our product offering is key to that. From keeping manufacturing facilities running safely using our signage, to identifying newborn babies in a hospital, to cleaning up oil spills, our products make a positive impact around the world. In the sections that follow, we highlight just a few of our products that make the world a better place.

Some of our core products that make the world safer and more productive include:

We are proud to offer a wide range of products that protect our customers and their operations and are extremely passionate about working with businesses in the renewable energy industry.

When Beneath the Waves Enterprises discovered the largest seagrass bed in the world in the Bahamas, they realized they were going to need help with their workflow to label the samples they were taking from the seabed. Seagrass meadows sequester carbon out of the atmosphere and store it in its root systems for hundreds of years.

The marine biology company reached out to Brady to help identify an alternative solution to logging information in three different places. Brady helped remove two steps from the process with a customized app. Brady’s M211 printer proved to be the right mix of durability and functionality in an environment with salt spray and large ocean waves, while our nylon cloth labels adhere in wet conditions.

With Brady’s solutions, Beneath the Waves will be able to process 72,000 square miles of these ecosystems in the Caribbean and in Europe.

With increasing pressure to transition to green energy, Alberta, Canada has become home to the most solar farms in Canada, and Brady's solutions are critical to both their construction and performance. The Travers Project is one of the largest solar power projects in North America, capable of producing 465-megawatts of power. Online sales giant Amazon was ready and waiting to buy all the electricity the solar farm can harvest in its effort to reduce its company emissions. The project cost $700 million to become a reality, including the construction of a substation that will take energy from 1.3 million solar panels and put electricity directly into Alberta's electric grid.

With trusted distribution partner Wesco, loyal end-users PCL, PTW and Seacliffe Electric, the specification for Brady products included the following:

Outdoor street lighting is important to create an inviting, safe and secure city-environment. The historic city of Verona, Italy and AGSM Lighting wanted to make it easy for the citizens of Verona to report light pole failures accurately, using their smartphone. AGSM Lighting wanted a way to link every light pole in the city to their web portal with a unique QR code.

Brady’s B-595 label material is an easy to apply, self-adhesive vinyl label that is resistant to UV-radiation, humidity and dirt, has a long lifespan, and is available in many colors. Brady’s i3300 Industrial Label Printer, equipped with the Brady Workstation software apps, allowed AGSM Lighting to print and label 55,000 light poles with unique QR code information. Each light pole now has an easily visible, unique identifier that improves communication with citizens and the efficiency of maintenance interventions.

One way that Brady works to make the world a safer place is by partnering with our customers to provide safety services using our industry-trusted expertise in lockout tagout, arc flash and confined space. Our field engineers help to identify potential safety gaps and help our customers create world-class safety programs in a variety of environments. In FY23, Brady performed:

ISO 14001 is a set of standards put forward by the International Organization for Standardization (ISO). Its purpose is to clarify the best practices for organizations that wish to reduce their environmental footprint by adopting an effective environmental management system (EMS). EMS systems are designed to monitor and report upon the environmental sustainability of a firm, for both internal and external stakeholders.

Join us on our journey towards a sustainable future!

We strive to be good stewards of the environment wherever our facilities are located.

Brady is committed to living our values by fostering a safe, inclusive environment that promotes dignity and respect for all.

Our mission is to support organizations that align with the Brady core values.

Winning the right way is a core Brady value and reflected in our leadership and business practices.