Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Enacted by Congress in 1970, the Occupational Safety and Health Act was a pivotal moment in U.S. labor law history. The pivotal decision assured American workers that their safety while working would become a priority. “Safe and healthful working conditions” were at the center of the law.

From the passing of this law, Congress created the Occupational Safety and Health Administration, otherwise known as OSHA. A federal regulatory agency, OSHA is charged with setting and enforcing protective workplace safety and health standards for a variety of industries.

Consider safety standards the starting point for regulations. While OSHA regulations are what industries must abide by, standards can be thought of as the guidelines for fulfilling those regulatory requirements, which are enforced by the government.

While OSHA legally ensures a safe workplace, free of hazards to workers across the country, they’re not the only regulating body for worker safety. Several other safety regulators exist, including the U.S. Department of Labor and the Employee Benefits Security Administration. These are all federal organizations, but there are also safety organizations at the state and industry level.

OSHA enforces its standards and regulations by conducting inspections — both high and low priority.

High-priority inspections are just that — a priority. They often follow a complaint, a situation of imminent danger, severe injury or illness or, of course, a fatality. Conversely, low-priority inspections occur regularly for high-hazard industries and typically take place as a follow-up to previously cited violations, often conducted via phone or fax.

No matter the type of inspection, OSHA measures compliance through evaluations of health and safety threats. The fewer threats an organization has, the more compliant it is with OSHA standards and vice versa. And protective measures play a role here, too. Think personal protective equipment or the use of certain kinds of instruments to measure a potential hazard. Putting these kinds of protections in place appropriately will put you in compliance.

Understanding OSHA is the first step to compliance — but what’s next? There are many requirements to operating an OSHA-compliant workplace, and you’ll want to follow all of them. From creating programs and policies to using signs, labels and tags — organizations must do their part to protect their workers and run a safe facility.

Worker participation and training can’t be emphasized enough. A critical part of maintaining a safe workplace is making sure everything is labeled clearly and encouraging employees to come forward with questions or concerns, without the fear of retaliation. Encourage participation. Provide access to all necessary information. And most importantly, lead training sessions on effective OSHA-compliance procedures

Put it in play — implement these safety standards:

A Hazard Communication Program (HCP) is a must for industries that use hazardous chemicals in the workplace. Not only is an HCP required by law, but it's also essential for employee safety. With that in mind, these programs should always be written and distributed to employees.

The HCP includes all processes for managing and maintaining safety. These processes vary from referencing safety data sheets to writing chemical, electrical or other hazardous materials labels on containers, as well as creating inventory lists and providing training for workers.

For all processes, make the language as universal as possible so it’s easy to understand and accessible for all employees. And label both the materials themselves as well as their containers.

There are great resources for staying on top of this requirement. Start with a copy of OSHA’s Hazard Communication Standard and familiarizing yourself with the specifics. Make sure you designate a manager to help facilitate the requirements that keep you in compliance. And consider investing in a GHS label printer for hazardous materials.

It’s important to review and reassess your written Hazard Communication Program periodically to ensure it still meets objectives. At the same time, review the existing labels in your facility to verify they’re up to date.

In addition to writing a clear HCP, create an Emergency Action Plan (EAP) to comply with OSHA standards. Important for workplaces of all sizes, here are the guidelines based on number of employees:

Regardless of the size of the organization, the purpose of an EAP is to facilitate a seamless response to workplace emergencies and, ultimately, minimize injuries.

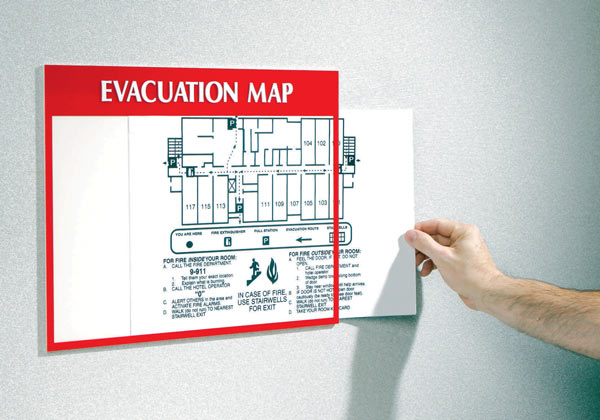

An EAP must include a means of reporting fires and other emergencies, evacuation procedures and emergency escape routes, a system to account for all employees following an evacuation, and rescue or medical duties.

To ensure the process runs smoothly, consider assigning an employee the responsibility of coordinating and practicing EAP procedures. And, since the installation of evacuation and shelter signs is related to an EAP, consider having the employee representative add that to their duties.

A Fire Prevention Plan (FPP), as the name implies, is designed to prevent fires at work. An FPP identifies the type of fuel sources present in the workplace that could initiate a fire or contribute to its spread. Major fire hazards, potential ignition sources and fire protection equipment may also be included in the plan.

The FPP should also include a review of the building's systems and their designated locations, including fire extinguishers, fire sprinklers and alarms. Fire and other emergency signs can be used in conjunction with an FPP to facilitate a safe building exit, ensuring OSHA compliance.

The types of signs, labels and tags your organization needs in a fire vary depending on the equipment and tools used at work. For facilities with hazardous chemicals, the proper handling and storage procedures should also be included. Right to Know (RTK) labels can be useful in the event of an emergency like this. For facilities working with electrical equipment, lockout devices are an essential aspect of an FPP, including circuit breaker lockout devices.

An exit route is defined as a continuous and unobstructed path from the workplace to a place of safety. A workplace typically must have at least two exit routes per building. The purpose of these routes is to facilitate the prompt evacuation of all employees in the event of an emergency. Employers should be sure to clearly mark exits, including both doors and stairwells.

As the name implies, walking-working surface requirements keep all surfaces that employees interact on safe. OSHA introduced this legislation in response to fall injuries, one of the leading causes of serious work-related injuries and deaths.

Employers must ensure that all places of employment are kept clean, orderly and sanitary — from passageways to storerooms, service rooms to surfaces and more.

These surfaces must be free of hazards, support the maximum intended load for that surface, and be regularly inspected. If surfaces aren’t safe, it’s up to employers to remedy the environment. This may require providing employees with a safe means of getting to and from walking-working surfaces.

When someone is hurt at work, fast action is imperative. That’s why employers are also responsible for providing medical and first-aid personnel and supplies. Training for each should be provided, especially for industries that deal with more hazards than most. For example, businesses dealing with hazardous chemicals should have the appropriate medical and first-aid supplies in case of an emergency.

All this being said, accidents happen. While OSHA requires businesses to maintain a safe workplace, they know this as well. That’s why a first-aid policy is a standard that complements the many other OSHA-required standards, like HPCs, FPPs, emergency action plans and emergency exit routes.

Many of the scenarios OSHA’s regulations protect against are focused on the worst-case scenario. Fires. Injuries. Emergencies. It all sounds pretty scary. But when you prepare for these scenarios, and comply with these time-tested standards, you’re protecting your team and your facility from those unlikely events coming to fruition. From the safety standards to the tools available — printers, signage and devices among them — you have all you need to assure your facility is in compliance and you can feel good about sending your crew home safely at the end of each day.