Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Labels for Safety, Visuals and Facility ID Desktop Printers

Labels for Product, Wire and Lab ID Benchtop Printers

Safety and Facility ID Desktop Printers

Product, Wire and Lab ID Benchtop Printers

Barcode Scanners and RFID Readers

PaintStripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Group Lock Boxes & Permit Control

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Calculators and Assessment Tools

Product Finders and Data Sheets

Get real value from choosing the right cable and wire labels & label printer

Cable and wire labeling is critical in the identification, assembly and repair of electrical control panels, wire harnesses, and data/telecommunications systems. It is an upfront cost that saves time and labor expenses when changes or repairs need to occur to the systems you work on.

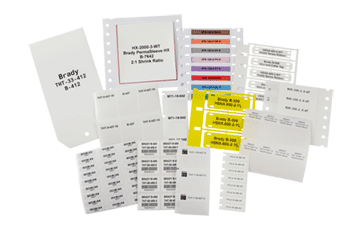

After following the appropriate wire color codes, there are several wire markers and cable labels that you can choose from; including heat-shrink sleeves, wrap-around cable labels, self-laminating labels, flags, and rigid tags.

Here are four key questions to answer that will help you decide what kind of marker or label is best.

Learn more about selecting the right wire marker for your application.

Determining the best label printer for the job is another key consideration. When choosing the perfect cable or wire label maker for your project, keep these questions in mind:

Portable label printers offer several benefits. When it comes to comparing a Bluetooth cable label printer (or Bluetooth wire label printer) like the M211 Portable Bluetooth Label Printer to a traditional portable label printer like the M210 Handheld Label Maker, start by answering the following statements:

If you answered yes to any of these questions, a Bluetooth cable label printer may be a better fit for your needs.

Ideal for un-terminated wires or cables needing superior abrasion and chemical resistance.

Ideal for general marking of terminated or unterminated cables and wires that may be curved or become curved.

Learn how to get real value by using the right labels with this guide on labeling wires and cables

Learn More

Your full start-to-finish solution to your Information and Communications Technology (ICT) identification needs

DOWNLOAD

Need to see a sample of our wire and cable marking labels? Request a free sample pack here.

Request a Sample