Getting Started With Label Automation

How to make the biggest impact with your automation investment

As technology continues its rapid advancement, the buzz around the use of automation and artificial intelligence in manufacturing grows. However, it’s proving to be more than just talk.

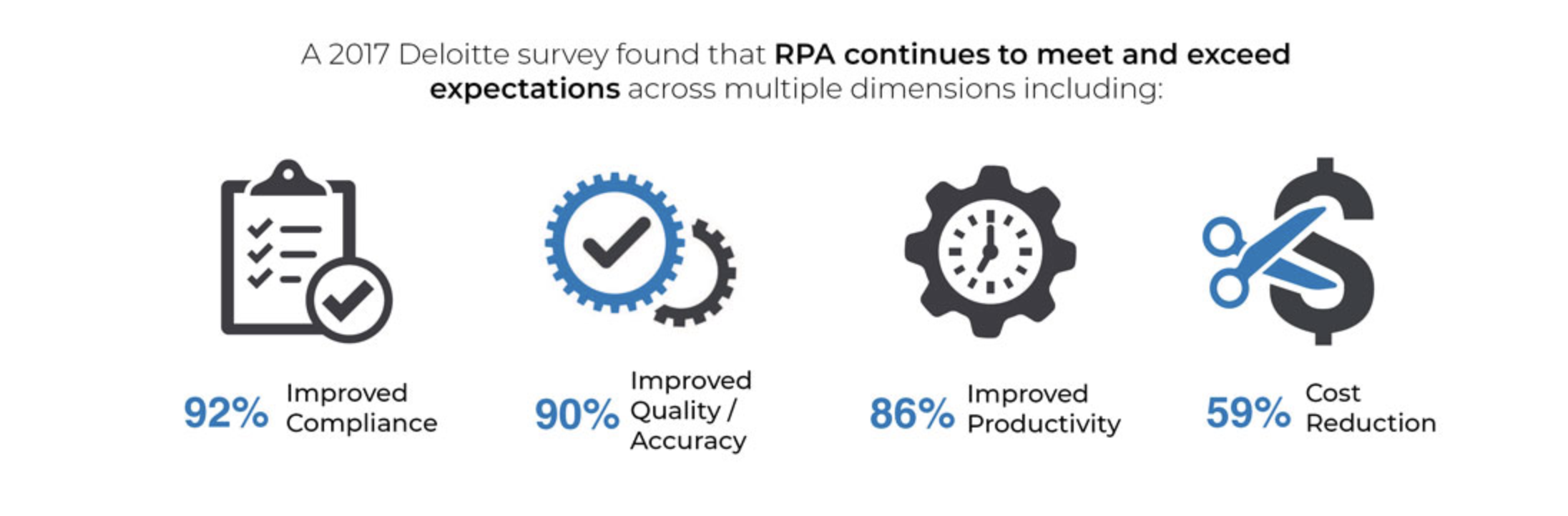

A 2017 Deloitte survey on Robotic Process Automation (opens in a new tab) (RPA) found 53% of the respondents were already using machines to perform jobs previously completed by humans. That number was predicted to increase to 72% by 2020, with an anticipated near-universal adoption by 2022.

The same study found that RPA investment payback was achieved in less than 12 months, with an average of 20% of full-time equivalent capacity provided by robots. Due to this, those who have already implemented RPA expect to significantly increase their investment in RPA over the next three years. That means, if you aren’t already considering how you can use automation in your own workplace, you’re likely falling behind your competition.

Figure 1. RPA performance data. Adapted from “The robots are ready. Are you?” by Deloitte, p. 2. Retrieved from www.deloitte.com/us/rpasurvey (opens in a new tab). Copyright 2018 by Deloitte Development LLC.

Making the most of your automation investment

If you’ve been paying any attention to the evolution of automation in recent years, you likely understand the benefits the technology touts — higher throughput, better craftsmanship, and reduced overhead. Too often, companies jump headfirst into their automation journey with a large capital expenditure, only to discover months later that the initiative isn’t performing as projected.

To ensure your automation investment delivers on expectations, your operation must fully map your value stream to identify bottlenecks, labor-intensive steps, and opportunities for improvement. Many times, simple process improvements or procedure changes can do as much to increase throughput as adding material handling, sophisticated robots, or sharp algorithms.

5 manufacturing areas that can benefit from automation

Automation should be viewed as a journey that requires careful planning and prioritization to be successful. Getting started isn’t too difficult when you begin with a simple framework. To start, review your business processes to identify those impacted by one or more of the following:

Ergonomic issues

The efficiency with which people perform their work is greatly impacted by tools, processes, and their roles; ergonomics aims to study and optimize these efficiencies.

Poor ergonomic processes result in reduced productivity and, worse, can impact employee health and safety. With a few inexpensive improvements, you can enhance ergonomics for material handlers, assemblers, operators, inspectors, and machinists with minimal impact on other areas.

To identify areas for improvement, look for ways to enhance the efficiency of your current workforce. For further advancements, consider lean manufacturing and continuous improvement principles. These principles can be adapted to boost throughput while creating a healthier work environment by reducing physically taxing tasks for employees. In some cases, backbreaking or exhausting work should be replaced by automated or semi-automated equipment.

Factory motion and movement

Creating a spaghetti diagram of your workflow is one of the easiest ways to identify motion inefficiencies in your production processes. A spaghetti diagram (opens in a new tab) is a visual representation that uses a continuous flow line to trace the path of activity through a process. These maps show the flow of material through production, which is often based on inherited old processes using unsupported products.

Visible material, equipment, and personnel movement through a factory is a sign of an unoptimized process. To improve these processes, many companies rearrange their facility to reduce walking time and shorten delivery routes, while others turn to powered cart delivery or add conveyor systems. People and products in motion can also be viewed as time waste that could otherwise be used to produce higher-value products.

Repetitive tasks

Steps that repeat are often good candidates for automation. Repetitive tasks are typically targeted for two reasons: they are easier to automate than more complex steps, and the work is tedious. Automating repetitive tasks becomes more desirable the more frequently the step repeats.

Consider an inspection process to check product weight and dimensions. The work is often completed by an individual who checks the weight on a balance and physically measures the part using a ruler or guide. Repeating this process 1,000 times daily could easily result in mistakes. Instead, a calibrated vision system and a mass balance driving a product lifecycle could allow a faster, mistake-free inspection and a quick green light to advance the work.

Now, consider the same process from the worker’s perspective. How would you feel if you spent half your day inspecting products? It’s likely you wouldn’t feel rewarded by your job. By freeing up the operator’s time to focus on steps that advance the craftsmanship of the product, their job becomes more rewarding.

Automation becomes a priority when a task is repetitive, escalates as an ergonomic issue, is non-value-added, or creates a bottleneck.

Rate limiting steps

Rate limiting steps, or bottlenecks, are the primary pain points of your operations. Increasing the flow of products through these bottlenecks is almost always guaranteed to offer a return on investment. While bottlenecks can be addressed by adding more shifts, capacity, or personnel, these changes can be costly and may not yield the best long-term return.

Bottlenecks are often targeted for automation because there’s an immediate need for improvement. While automating certain steps may be more expensive in the short term than adding an operator, the long-term impact often justifies the effort.

It’s important to note that fixing one bottleneck can sometimes create another, making your investment seem less impactful. For this reason, mapping out the capacity of each step in your process is crucial to fully understand the value an automation project can bring.

Non-value added steps

It may sound odd, but many efficiencies are lost on tasks that don’t directly impact the value provided by your products. Non-value-added work can be mandated by external or internal sources, and customers aren’t willing to pay more for this additional work. However, that doesn’t mean the work can be avoided.

Inspections and labels are good examples of non-value-added steps. Consider your quality management system: the product has to work, but customers may not care about the lengths you took to ensure that. It’s important to ask yourself:

- How can I keep my Defective Parts Per Million (DPPM) low with less effort?

- Can I automate my tests and inspections to save time and money while still delivering exceptional quality?

Now, consider your internal traceability program. You know you must batch and serial label all the goods you produce to limit liability or loss in the event of a quality incident, investigation, or recall. However, many customers see traceability as a non-value-added step rather than recognizing the value it provides. If your operators are spending a significant amount of time typing or handwriting label data, you’re likely not being efficient with this required work.

Where do I start?

The daily management of production schedules and activities keeps manufacturers busy. Typically, this management is broken down into several focus areas, such as warehousing raw materials, assembly, and packaging. Each of these functions may exist as a separate and dedicated area or be integrated into other processes.

For quick reference, we’ve rated each functional area against anticipated improvement areas related to the five most common automation objectives. These representative ratings are based on our experience helping customers drive cost savings through automation assessments and consultations.

| Process steps | Non-value add | Movement | Ergonomics | Repetition | Bottleneck | Cost to implement |

|---|---|---|---|---|---|---|

| Warehousing | Med | High | Med | Low | Low | $$$ |

| Labeling | High | Med | Med | High | High | $ |

| Converting | Low | Low | Med | High | Low | $$ |

| Assembly | Low | Med | Low | High | Med | $$$ |

| Inspection | Med | Low | Low | Med | High | $$ |

| Finishing | Low | Low | Med | Med | Med | $$ |

| Packaging | Low | High | Med | High | Low | $$$ |

Ratings based on more than 100 individual automation assessments across more than 5 different industries.

Warehousing

Warehousing encompasses all efforts to source, procure, receive, approve, inventory, and deliver raw materials used to manufacture a product. Common issues include movement inefficiencies, material storage challenges, and ergonomic concerns such as searching for and retrieving raw materials.

Labeling

Labeling comprises all elements of proper product marking, including correct data from the Enterprise Resource Planning (ERP) system, work order management, batch control, serialization, regulatory and compliance, product inspection, finishing, branding, and packaging. Due to the interconnected nature of labeling with other process steps and the low cost of implementing automation solutions, it’s often one of the first projects undertaken.

Converting

Converting steps transform raw materials into value-added products through processes such as cutting, molding, stamping, brazing, or other physical transformations during production. Many of these steps involve challenging and repetitive tasks, making them prime targets for improvement due to employee health and safety concerns or their potential to create bottlenecks in the value stream.

Assembly

Assembly encompasses all the necessary additive manufacturing processes, such as fixing, welding, fastening, and soldering, and its often repetitive nature makes it a prime candidate for automation, which can enhance the consistency and quality of finished goods; however, assembly also necessitates the timely arrival of numerous parts, potentially causing inefficiencies in material movement, and because it typically integrates multiple raw material streams into a single product, it frequently represents the production bottleneck.

Inspection

Product inspection stands as a vital step in meeting customer requirements and expectations, with the quality of this process capable of significantly impacting a business, even though these diagnostic tests don’t directly enhance product value; this inspection work can be repetitive and contribute to bottlenecks, particularly with 100% inspections, making quality control efforts a frequently recommended and relatively affordable initial project for manufacturers aiming to advance their automation capabilities.

Finishing

Finishing steps include any final aesthetically or functionally oriented procedures that complete the product. As the final stage of production, these steps are often value-added and may involve product customization, meaning they aren’t necessarily repetitive. Finishing processes are most often automated when they create a bottleneck or represent the bulk of the work in the value stream.

Packaging

The packaging process is frequently identified for automation to drive cost savings. While packaging automation projects can be expensive, many solutions exist across a variety of price ranges, as most manufacturers face similar challenges. These solutions can provide additional benefits if you operate a distribution center within the same facility as your manufacturing operation. Pick-and-fulfillment automation can enhance employee productivity and help you meet same-day shipping goals, supporting the just-in-time manufacturing model.

Considering cost

Automating your production areas can be costly, which is why it's important to weigh the opportunity cost of addressing a single large objective versus making multiple smaller incremental changes. Remember that the lower the cost to implement, the faster the return is seen. If completed as part of a larger automation initiative, the increased bandwidth from several smaller projects can be reinvested to address other objectives.

Considering the cost and the five principal reasons to automate, we recommend looking at labeling automation as one of your first projects. Labeling isn’t always a separate function—it’s often integrated into converting, inspecting, finishing, and packaging processes.

Start by evaluating how keystroke or transcription errors, label printing, and label application slow down your operations. Automating or semi-automating your labeling process requires little upfront investment, yet it can dramatically reduce errors and time spent fulfilling non-value-added regulatory, commercial, and traceability requirements.

We're here to help

It’s a good bet that product labeling should be one of your first automation projects. Take a quick assessment if you’re interested in a free labeling automation assessment, and we’ll set up a phone consultation or site visit.